The more our daylight hours decrease, the more we need the light!!! The building construction is picking up. With concrete, wall framing, and rafters, we are happy to see some progress. We had planned to have the production section of the building up and ready for fermentation in time for us to process our first load of grapes... Unfortunately, there have been some delays, and we've had to adapt and overcome.

Pads for Production

Prep Work

Before any concrete could be poured, the ground needed to leveled and pounded to settle the gravel. The floor was then reinforced with rebar for added support since we will be driving on it with the forklift.

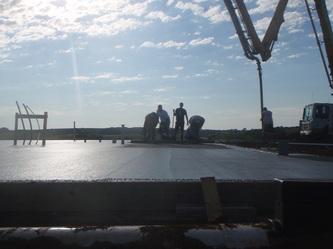

8.25.10

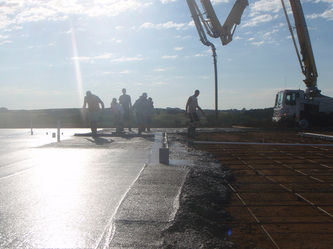

The gentlemen from R C Concrete were there bright and early at 7:30 AM to get started on the production pad. This area will hold the fermentation tanks, the lab, utilities, wine storage, and barrel room. A bit more complicated to pour due to it all needing to slope to the drains.

This summer I have really learned to appreciate the work that goes into concrete pouring. It is an intense process... Consistency, timing, tools, and speed all seem to be stressed, but these boys have it down like clockwork. Because of all of the sloping for drainage needed in the production room, it all needed to be handscreeded.

Slump Test

Like most things, adding water to concrete will dilute it's ingredients, reducing the quality of the concrete. It does, however, make it easier to pour, work with, and clean up so from what I hear, it is very tempting to add water...

Will did a "slump test" on each concrete load to check the consistency of each load and how hard the concrete was before it cured.

Will did a "slump test" on each concrete load to check the consistency of each load and how hard the concrete was before it cured.

Will on the last step of the slump test, tapping the cone with the rod on both sides two times, lifting up the cone, and measuring how many inches the concrete "slumps". Ours had a bit of a range, between 4 and 6 inches... We were looking to have 4 inch slump, but the concrete turned out beautifully and with the reinstatement of the rebar it should be good and strong.

The boys applying the finishing touches to the production area.

Working on the crush pad.

Our crush pad (outdoor) will be used for unloading our grapes from macrobins into the crusher/destemmer using a forklift with a rotating attachment. (Forklift supposed to be here last Friday, 9.3.10---not going to be here until Tuesday...) The crush pad will also be used for pressing the grapes/must. They were able to power screed this area and the applied a brush finish so the surface wouldn't be "slippery when wet".

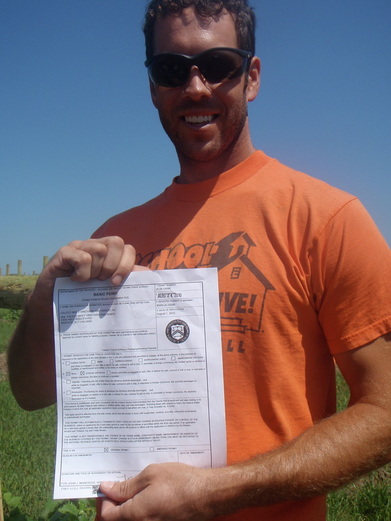

Our business name was accepted by the U.S. Patent and Trademark Office! We are officially

Calico Skies Vineyard and Winery, Inc. So we put it in concrete...

Calico Skies Vineyard and Winery, Inc. So we put it in concrete...

Will spraying our new concrete with water to help it cure more gradually to reduce cracking in unwanted areas.

Temporary solutions

It's been a roller coaster ride of emotions. Good news... We have concrete! But it'll take a couple weeks for it to cure and be strong enough for us to drive on... Therefore, bad news. We still had no where to process our grapes that we would be getting the following week... Good news! We had a refrigerated trailer on it's way...

Bad news... It had been a couple years since it had been running. Good news! Bill from H & H Repair (Inwood, IA) was on his way...

It just needed a dose of freon and it was back in business!

Legalities

We received the Federal Bonding for our Winery!

Vineyard

Still trying to get those shoots up on the trellis and off the ground! We've had lots of help lately. Will's mom made it from central Iowa and we accomplished much tying of shoots and nailing up of wire.

Vines were still growing pretty vigorously! 8.28.10

Before... 8.28.10 After...

Because we got a bit behind in putting up our trellis the shoots started to grow together quite a bit making it difficult to tie them up once we got the trellis up. We took out the bamboo stakes and separated the shoots and tied them onto the trellis. 8.28.10

Ouch! Buffalo Burr=free acupuncture. Seeing some disease in the vineyard (anthracnose) disease control will be our main focus next year in the vineyard.

Aronia Update

To come back to our test run... We let the aronia berries sit on their skins around four days, (8.22-8.26), then it was time to try out our press for the first time, and break in our new 80 gallon variable capacity tank.

Readying the equipment!

Loading up the press!

Pressing the aronia!

Now we wait until the fermentation is near completion, then we will rack the wine off of the settled yeast, and other particulates.

The First Official Fermentations

With our temporary production facility in order, and the government happy, we started off on our road trip four hours away (Mitchell, IA) to to pick up our first load of grapes.

Will couldn't contain his excitement...

We were kind of late in the game for finding grapes, so we weren't sure what we would find when we got there. We arrived to pales and pales full of beautiful La Crescent grapes! Relieved and excited, we started cleaning, sulfiting (keep them free of bacteria and micro-organisms), and adding a chunk of dry ice to the macrobins. The dry ice was added to keep the grapes cooler as well as surrounding them with CO2 to protect them from oxygen during the trip home. We also sprayed them with a sulfite solution to keep them from starting to ferment.

La Crescent

Approximately 2200 lbs of La Crescent were picked. We plan to make a delicious dry to semi-sweet white wine. Common descriptors are: apricot, peach, citrus, and floral. It would be similar to a Riesling (if it has floral aromas), or possibly a Sauvignon Blanc (if it has aromas of citrus).

Marquette

2200 lbs of Marquette as well. Common descriptors of wine made from Marquette are: Cherry, berry, black pepper, and spice. Similar to what a Cabernet Sauvignon might taste like.

Because there was such great help, we were able to hang around the macrobins and transfer the buckets to the bins while sorting out the MOG (material other that grapes) and any clusters that weren't up to par.

Frontenac Gris

Approximately 1500 lbs of Frontenac Gris. We plan to make more of a dessert style wine out of this. Common descriptors are: peach, apricot, citrus, and tropical fruit with a wine coloration of pink/peach.

Many vineyards in Iowa were hit by a late frost on Mother's Day (May 7th, 2010), which hurt their yields dramatically. Luckily this vineyard didn't receive much damage and yields were good. I was impressed with the canopy, the grapes had good exposure to the sun, and the disease was at minimum. The couple hopes to open a winery someday soon, so look for it on the map in Mitchell, IA (Northeastern IA) within the next couple of years. They, too, have been attending Des Moines Area Community College to become certified in Viticulture and Enology.

We were also hoping to purchase around 2000 lbs of Frontenac, but our load was getting a bit heavy and we had a four hour drive back home ahead of us... Common descriptors of Frontenac are: cherry and black currant, I have tasted a few that resemble what a Merlot might taste like. We will be receiving Frontenac from a vineyard in Maxwell, IA within the next couple weeks to make up for what we weren't able to pick up. We have a few different ideas on how to process the Frontenac... Possibly blend with Marquette to increase complexity, or make a varietal wine (75% Frontenac), or possibly a "Port" style wine.

This is just the beginning of our grapes/juice. We were hoping to process a total of 16 tons of grapes this year. Due to the low yields Iowa grape growers have been experiencing, we are still on the search. We will be getting juice (grapes that have already had the juice pressed out of them), in October. Concord, Catawaba, Brianna, and possibly Traminette, are among the cultivars we will be receiving.

Gulp...

As I said before, we were worried our load was getting a bit too heavy for the truck/trailer to handle... The first picture below, case and point. Thankfully we had some help from the picking crew to solve this dilemma. We were able to flip the hitch around and gain four inches in clearance.

In order to record the amount of grapes received, we weighed the truck and trailer empty, and full of grapes. We did make it home safely, all bins and grapes accounted for. Phew!

More to Come!

Much much much more to come... I have gotten a couple weeks behind in my postings and quite a bit has been happening... I will be posting again soon!

RSS Feed

RSS Feed