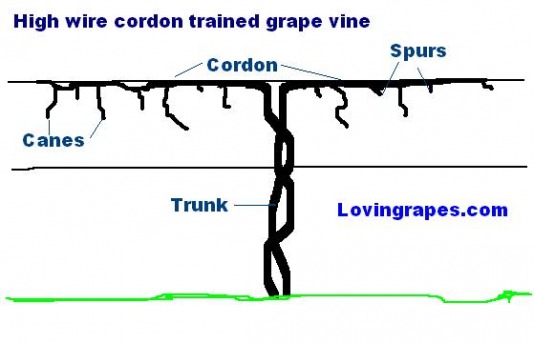

We made a lot of progress last weekend. We are 100% completed with the post pounding in the "Middle Place". Will's dad came out from central Iowa to help, and they were movin'. We have also begun stringing the wire from post to post in the row. My mom and Aunt were a big help getting that started. We can NOT wait to get the vines growing up on the wires.

We have finished tying up the vines on the "Knoll", and they have already started to take hold and grow into their new home.

So... LET THE POUNDING CONTINUE.

8.12.10

There was no time wasted as we moved our focus to the "Middle Place". The 4"x8' posts go in pretty smoothly... However, the 5"x8' posts that we use for the posts at the very end of the rows, can be buggers.

Will attempting to make some minor adjustments...

Dogs on the prowl for rodents...

8.18.10

The Kimberley Duo

When Will's dad came into town, he meant business... These boys pounded around 60 posts in 3 days and constructed nearly 40 H-braces. The weather was muggy, and hot. But they powered through despite it all.

Girl Power

While the boys were pounding, the girls picked up their hammers and tape measures. They measured and marked the posts at 62" and 36" and nailed each wire at the those heights.

Dad also frequents the vineyard when he's not doing the million other things on his list... Tendril tying is his favorite. He has also been helping Will finish up the H-braces, and tightening and splicing the wire.

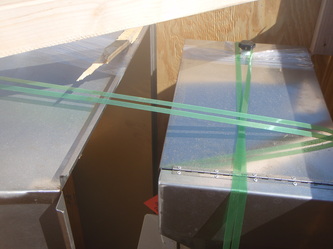

Vents and Pipes.

GNR Plumbing out of Inwood, IA came out to install the in floor ventilation distribution system for the heating and cooling in the tasting room, and pipes for the geothermal heating and cooling system. We will have three separate zones controlling the production room, tasting room, and events.

It's Electric!

8.17.10

We now have electricity wired to the building!

We now have electricity wired to the building!

We began digging the trench for the electric conduit in to the utility room for production so we can later run the electric lines through the production room... Dan (Dan's Electric-Inwood, IA) and his crew came to finish things up...

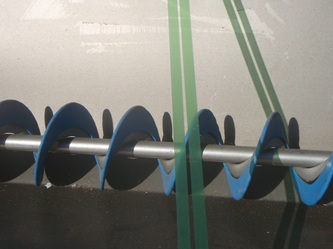

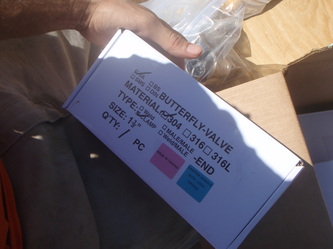

Shipment of Equipment

Crusher, destemmer, and hoses with fittings.

Macrobins, gaskets, glass lab ware and filters...

These are a few of Will's favorite things...

Macrobins, gaskets, glass lab ware and filters...

These are a few of Will's favorite things...

This is our "plate and frame filter" all packaged up. This will be used to remove any yeasts and/or particulates that hadn't settled to the bottom of the tank while fermentation/aging.

What it should look like when we have it together.

The larger hose will be used for transfers of juice and skin (must), and the smaller hose will be used for transfers of juice and wine. In amongst the hoses is our barrel washer.

The excitement continues!

Our second shipment contained 5 boxes of goodies...

Test Run.

Aronia berries - packed with anti-oxidents, higher than grapes and blueberries, for example. We were contacted by a local farmer asking if we might be interested in fermenting some of his backyard berries. And we said, "yes!" As we just got our equipment in, this was our chance to break it in.

The aronia berries have high tannin, (the dry feeling in the mouth), VERY high pigmentation, and it was picked at a low sugar (brix) content. The juice, however, was delicious.

The aronia berries have high tannin, (the dry feeling in the mouth), VERY high pigmentation, and it was picked at a low sugar (brix) content. The juice, however, was delicious.

Berry picking crew Will testing the sugar (brix).

The Crush.

Personally I've always been one to be a bit disgusted by the berry stomp idea... But now I say... Don't knock it 'till you try it! We had a great time.

The boys making the sugar additions. We needed to add sugar so we can ferment to around 12% alcohol, for stability of the wine.

Concrete and the Real Deal.

Up next... Pouring the floor to the production room and exterior concrete pad, and the grape scramble...

RSS Feed

RSS Feed