We have been busy! In a good way. From growing vines, to delicious wines, and a building to make it all come together, things are going well.

9.3.10

Putting up the first walls of production! This is facing the South.

Putting up the first walls of production! This is facing the South.

9.4.10

Labor Day Weekend

What better way to celebrate Labor Day Weekend, than to labor??? Our friends from Chicago took a break from the windy city to step onto the Iowa soil and get dirty. We accomplished much in the vineyard; finishing the end posts, and tying up the vines.

9.5.10

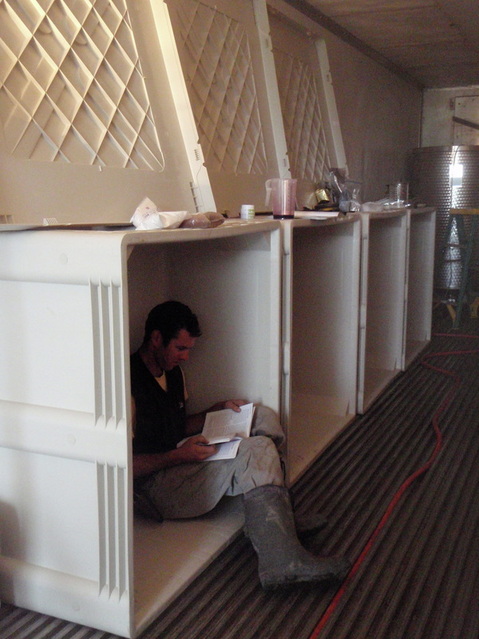

Punching down the cap of the Frontenac!

Punching down the cap of the Frontenac!

As the CO2 is released from fermentation, solids float to the top, forming a "cap". Will is "punching down" the cap to mix the skins back in to the must for extraction of color and flavor.

A toast to all that was accomplished!

Delivery! 9.7.10

Our Flexible Impeller Pump! Variable speed, can be used to gently transfer wine and must, (grape skins, and juice or wine). This is what is going to make our lives livable. And, thus far, it has worked amazingly.

Frontenac and Marquette pressed. 9.8.10

As we gradually moved from processing in the back of the refer trailer to our concrete processing pad, things got better and better... This was the first time we were able to use our pump, which we call the "Viking King". This was a small batch, 50 gals, we picked up much more Frontenac in the weeks following...

FRONTENAC

MARQUETTE

Raindrops are falling on my head... As we began our prep work for pressing the Marquette, it began to rain... We did get a tent up to protect everything while we were processing, but our documentation stops here.

Inoculation 9.9.10-9.10.10

We had left our crushed and pressed white juices in stainless steel tanks to cold settle in the refer trailer... It was time to inoculate with yeast, so we moved the Viking King (our pump), back to the other end of the plywood path.

FRONTENAC GRIS

Testing the Brix (percent sugar) of the Frontenac Gris juice. At 22 Brix it should ferment out to 11% alcohol after fermented to dryness.

The water was warmed and yeast added for it to be rehydrated. Will gradually added juice (incremental juice additions) to the yeast to not sugar shock to yeast, and to not cool the yeast down too much before adding it all into the tank.

LA CRESCENT

We went through the same process for the La Crescent. Racking the juice off of it's sediment into a new tank, then testing the brix, gradually adding the juice to the yeast, and adding it all to the tank.

Men at Work.

Stouwies Construction Crew putting it all together.

Decisions, decisions...

We went with the "Burnt Sienna" shingles shown in the picture on the right.

Stains we are considering for the cedar siding. "Honey Gold" for the trim, and "Cedar Naturaltone" for the siding.

9.12.10

9.14.10

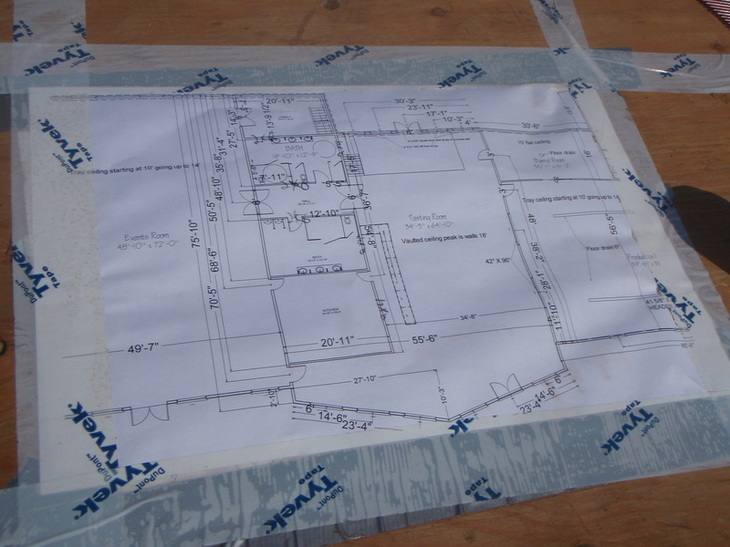

Discussing some minor changes to the design...

Wendall with the solution. We now have an angled corner wall to expand the vista in the tasting room. So happy we decided to make that change, and that is was able to be done!

Frontenac vines all tied up and ready for fall!

More of September to come, had to send the computer that has all of the pictures on it in to get it fixed...

RSS Feed

RSS Feed