1.30.11

Dry-wall installation has begun in the tasting room, which will eventually be covered up by pine planking. A relief that we don't have to paint this ceiling, however this means we are back to staining...

The guys installed our roll-up door to our cellar...

1.31.11-2.3.11 Texture and Paint in the Sky Room (Events Room)

2.4.11 A walk in the vineyard at sunset...

2.7.11-2.9.11 Pop Champagne!

Will began paining the ceiling with our "Champagne Bubbles" color in the events room. It's all in the name ;o).

2.10.11 More painting and... Staining...

While we finished up the painting, Will's mom started up our next staining project... 900 pine boards for the ceiling in the tasting room. This is turning out to be quite different from staining our siding, which was a one step process, compared to sanding, applying a wood conditioner (let dry), apply the stain color (let dry), apply a coat of polyurethane (let dry), sand and apply another coat... Currently finished with 200 boards, really looking forward to the next 700. ;o)

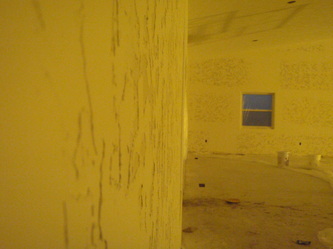

Will also started our East wall that we have chosen to do a painting technique to, called "moonlit weave". Also a multi-step process, he started by spraying on the base coat, with me rolling behind him... This will be the wall that we will have the electric-roll-down screen (certainly not the technical term), for the projector.

2.11.11 Step two.

2.15.11 Sky Room nearing completion...

We received our tables and chairs we will be using for events! We have 38 60" round tables, 6 rectangular 8' tables, and 300 chairs for events that will take place in the Sky Room. The round tables can fit 6-8 guests, the rectangular 10 guests. We have our first private event booked the first weekend in May, and we are super excited!

All that needs to be finished in the Sky Room is staining and installation of the woodwork, staining of the concrete, and installation of the chandeliers, of which have all arrived that the Echo Lighting showroom in Sioux Center!

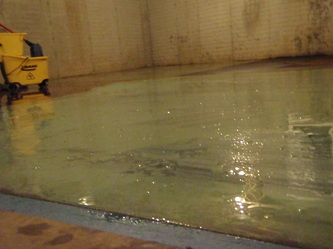

Testing out the concrete stain.

Tried four different colors: weathered bronze, black, walnut, and petina, in the basement to figure out what we will want to use in the Sky Room, Tasting Room, and Barrel Room. We still need to decide on what sealant coat to use, so we are open to any suggestions!

2.17.11 Wrapping it up.

Since the siding was finished, we could focus our attention to the pine planking for the tasting room. Using sheets of sand paper and sanding by hand, quickly progressed to electric palm sanders, making the process easier on the arm. We have learned it best to start the hardest way of doing things, then moving to a simplified way makes us much more appreciative of the whole process. ;o)

RSS Feed

RSS Feed